-

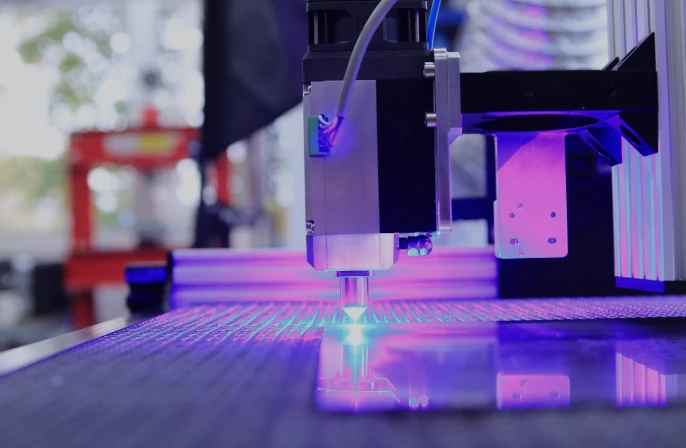

Laser marking

Product traceability is essential to meet the high quality requirements of industry.

For this reason, laser marking is used by manufacturers to automate marking operations and thus guarantee 100% control of their processes.

Laser marking technology is particularly used for direct and permanent marking of metal or plastic parts depending on the hardness and their surface condition.

Industrial laser marking is recommended for mass production, where speed and accuracy are required.

-

Principle

Laser engraving is mainly used for direct and permanent marking on all types of material, from plastic to metal parts, irrespective of their hardness and surface condition.

Our laser engraving machines can mark all alphanumeric characters, logos, 1D and 2D standard codes (datamatrix, QR code…) with precision and contrast.

The laser is recommended for applications with high rates and an important marking requirement.

Depending on your needs, you can add options such as 3D marking or integral reading systems at any time.

We can adapt all our laser marking machines to your particular specifications.

-

Benefits

• Precision and fineness of markings

• Versatility of applications and materials

• Integration flexibility

• Very high definition marking (fibre technology)

• High rates: medium to large series

• Very high rate marking

• Used via standalone or integral stations

• Reliability & Endurance

• No consumables